Offset PVC Sheet Printing PVC Coated Overlay With Yellowing Resistance

Product Details:

| Place of Origin: | China |

| Brand Name: | MK |

| Model Number: | MCO-W |

Payment & Shipping Terms:

| Minimum Order Quantity: | 20000 sheets or 2 tons |

|---|---|

| Price: | Negotiable |

| Packaging Details: | by reel or 500 sheets per bag / 4-8 bags per paper carton , or as per customer requirements . All the cartons are firmly piled up and fixed on the solid plywood pallet |

| Delivery Time: | 10-15 work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10 million square meters per month |

|

Detail Information |

|||

| Package Method: | 500 Sheets Per Bag / 4-8 Bags Per Paper Carton, Or By Reel, Or As Per Customer Requirements | Size: | In Reel Or Sheet, A4, A3 Or As Per Customer Requirements |

|---|---|---|---|

| Thickness: | 0.04,0.05,0.06,0.08,0.10mm Or Other | Peel Strength (90°, 300mm/min): | ≥ 6.0 N/cm |

| Feature: | With High Adhesion | Color: | Transparent With One-side Glue Coating |

| Highlight: | pvc overlay sheet,film frame overlay |

||

Product Description

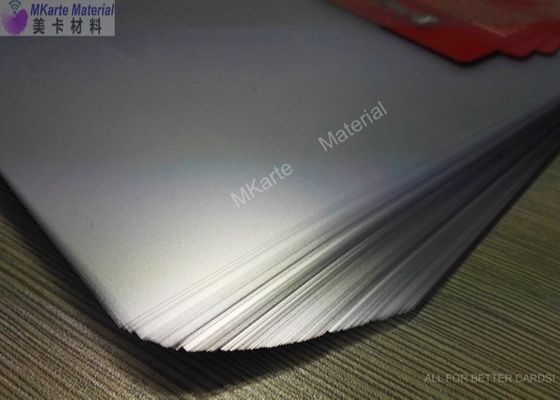

Plastic Card Making Material - PVC Coated Overlay Film With Yellowing Resistance

PVC Coated Overlay Film MCO-W ( strong adhesion level )

Which also can be used as for the offset PVC sheet printing . We also call the PVC coated overlay as PVC coating film for card body lamination , Coated film for card production , glue coated film for card , glue coating overlay for plastic card , card plastic material , card body plastic material

| 1. PVC Strong Coated Overlay Film Introduction |

PVC Strong Coated Overlay Film with Strong initial viscous force , slow decline , yellowing resistance ,

deformating resistance after laminating .The surface is smooth , and easy to use. Mainly used for protective

film of bank card , social security card , IC card , RF card and other card with higher requirements .

PVC Coated Overlay MCO-W model is suitable for laminating with most PVC sheets printed by various printers . It features high adhesion , no color change and deformation .

It is applicable to almost all sheets printed by various ink . It features excellent peeling strength and long aging time .

Technical Parameters:

| Item | Unit | Value | |

| Density | g/cm3 | 1.26 ±0.04 | |

| Tensile Strength | Horizontal | MPa | ≥35 |

| Vertical | ≥40 | ||

| Vicat 5kg | ℃ | 72±2 | |

![]()

![]()

| 2. PVC Strong Coated Overlay Film Specification |

| Item | Parameters |

| Vicat softening point | 72±2 ℃ |

| Heating Shrinkage ratio | ≤ 10 % |

| Tensile Strength | ≥ 40 MPa |

| Normal thickness in mm | 0.04 , 0.05,0.06,0.08,0.10 |

| Peel Strength (90°, 300mm/min) | ≥ 6.0 N/cm |

| Aging time (65℃ temp./95% humidity ) | >200 hours |

| Suitable ink | offset and silk screen printing UV ink, Pigment and dye ink for inkjet printing as well as digital printing ink |

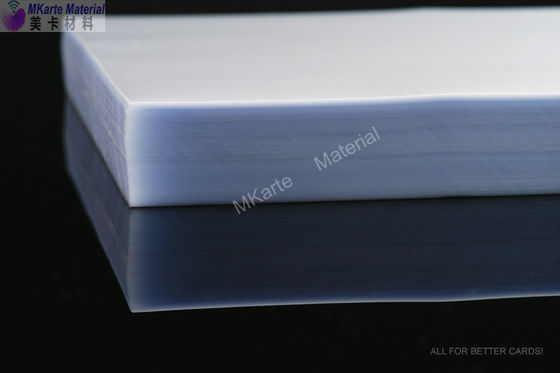

1. Size : in reel or sheet , A4 , A3 or as per customer requirements

2. Normal thickness : 0.04,0.05,0.06,0.08,0.10mm

3. Color : transparent with one-side glue coating

4. Package method : by reel or 500 sheets per bag / 4-8 bags per paper carton , or as per customer requirements

5. Storage condition: Sealed , moisture-proof , room temperature under 40℃ , Keep it horizontally, avoid heavy pressing and direct sunlight .

* Customer design can be accept.

3. Applications of PVC Strong Coated Overlay Film

![]()

| 4. Packing of PVC Strong Coated Overlay Film |

![]()