Low Dust PVC Uncoated Overlay Film With No Color Change And Deformation

Product Details:

| Place of Origin: | China |

| Brand Name: | MK |

| Model Number: | MUO-G1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 20000 sheets or 2 tons |

|---|---|

| Price: | Negotiable |

| Packaging Details: | by reel or 500 sheets per bag / 4-8 bags per paper carton , as per customer requirements . All the cartons are firmly piled up and fixed on the solid plywood pallet |

| Delivery Time: | 10-15 work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 3 million tons per month |

|

Detail Information |

|||

| Size: | Sheet Size Or Roll Size | Thickness Range: | 40-100 Micron |

|---|---|---|---|

| Package Method: | In Reel Or 500 Sheets Per Bag / 4-8 Bags Per Paper Carton, Or By Reel, Or As Per Customer Requirements | Color: | Transparent Without One-side Glue Coating |

| Storage Condition: | Sealed, Moisture-proof, Room Temperature Under 40℃, Keep It Horizontally, Avoid Heavy Pressing And Direct Sunlight | Application: | Used For Lamination With Partially Or Less-printed PVC Sheets |

| Highlight: | pvc overlay sheet,film frame overlay |

||

Product Description

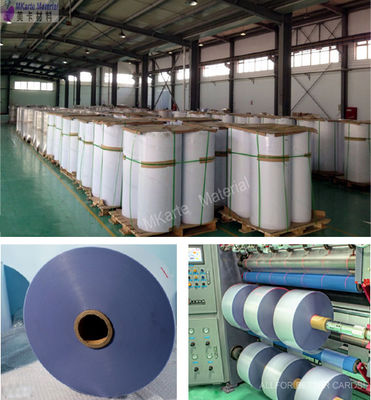

PVC Uncoated Overlay Film in Roll MUO - G1 for PVC Card production industry

PVC uncoated overlay Film MUO-G1 model is used for lamination with partially or less-printed PVC sheets . With the right lamination parameter setting , It can also realize high adhesion , no color change and deformation.

Overlay without a layer of thermal glue on the surface .It is mainly used to make the external film of credit cards and other cards.

| 1. PVC Uncoated Overlay Film - Descriptions and Characteristics |

PVC uncoated overlay Film MUO-G1 model is used for lamination with partially or less-printed PVC sheets . With the right lamination parameter setting , It can also realize high adhesion , no color change and deformation.

Overlay without a layer of thermal glue on the surface .It is mainly used to make the external film of credit cards and other cards.

![]()

Characteristics:

1. Excellent stable quality

2. Special formulation according to each client's requirement

3. Exact sheet size cutting and thickness control

4. Low dust

5. Low static

6. Adjustable Vicat degree

7. Less than15 days Short Lead Time

8. Perfect packaging for transportation

9. Best after sell service

| Item | Unit | Value | |

| Density | g/cm3 | 1.26 ±0.04 | |

| Tensile Strength | Horizontal | MPa | ≥35 |

| Vertical | ≥40 | ||

| Vicat 5kg | ℃ | 72±2 | |

| 2. PVC Uncoated Overlay Film - Specification |

Technical Parameters:

| Item | Parameters |

| Vicat softening point | 72±2 ℃ |

| Heating Shrinkage ratio | ≤ 10 % |

| Tensile Strength | ≥ 40 MPa |

| Normal thickness in mm | 0.04 , 0.05,0.06,0.08,0.10 |

| Peel Strength (90°, 300mm/min) | ≥6.0 N/cm |

| Aging time (65℃ temp./95% humidity ) | >200 hours |

| Suitable ink | offset and silk screen printing UV ink, Pigment and dye ink for inkjet printing as well as digital printing ink |

1. Size: Sheet size or Roll size , A4 , A3 or as per customer requirements

2.Thickness range: 40-100 Micron

3. Color : transparent with one-side glue coating,Transparent (Clear)

4.Roughness: Both sides matte

5.Vicat point: 72+2 ℃ (ISO306B50)

6. Package method : by reel or 500 sheets per bag / 4-8 bags per paper carton , or as per customer requirements

7. Storage condition: Sealed , moisture-proof , room temperature under 40℃ , Keep it horizontally, avoid heavy pressing and direct sunlight .

* Customers' design can be accepted.

| 3. PVC Uncoated Overlay Film - Application |

![]()

![]()

| 4. PVC Uncoated Overlay Film - Inspection , Package and Storage |

![]()

![]()