A4 A3 High Adhesion PETG Plastic Sheet Coated Overlay

Product Details:

| Place of Origin: | China |

| Brand Name: | MK |

| Certification: | ISO9001 |

| Model Number: | MCO-PETG |

Payment & Shipping Terms:

| Minimum Order Quantity: | 30000 sheets or 2 tons |

|---|---|

| Price: | USD 0.5-3 USD/sheet |

| Packaging Details: | By roll or 500 sheets per bag, 4 or 8 bags per paper cartons which are piled up and firmly fixed on solid plywood pallets |

| Delivery Time: | 10-15 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10 million square meters or 3 million tons per month |

|

Detail Information |

|||

| Color: | Transparent | Peel Strength (90°, 300mm/min): | ≥6.0 N/cm |

|---|---|---|---|

| Density (g/cm3): | 1.20 ±0.05 | Heating Shrinkage Ratio 105 ℃/10min : | ≥-8.0 % (longitudinal) &≥-4.0 %(transverse) |

| Aging Time (65℃ Temp./95% Humidity ): | >200 Hours | Suitable Ink: | Offset Printing And Silk Screen Printing UV Ink |

| Highlight: | High Adhesion PETG Plastic Sheet,A3 PETG Plastic Sheet,A4 PETG Plastic Sheet |

||

Product Description

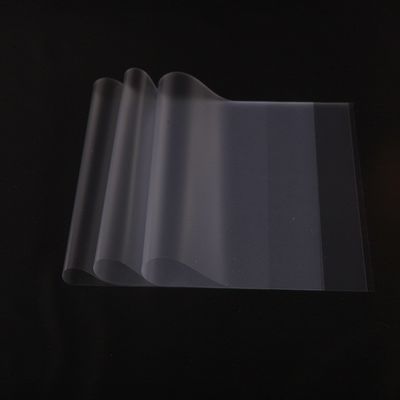

High Adhesion PETG Plastic Coated Overlay Perfect Application For Anti Fake IC Cards

| 1. General Introduction for High-adhesion PETG Coated Overlay or Film for PETG Plastic Card Body Production |

It is a new developed environment friendly product which could get excellent peel strength at low laminating temperature. It provides superior aging resistance performance to other similar products and no deformation and color change after lamination. It could be used for laminating pure PETG card (both overlay and sheet are PETG).

It has such features as impact resistance, high temperature resistance, anti-static, abrasion, folding and high strength. It is widely used for the production of high-end credit cards, ID cards, special packaging and printing industry.

PETG is a kind of transparent amorphous co polyester.

![]()

| 2. Specification for High-adhesion PETG Coated Overlay or Film for PETG Plastic Card Body Production |

PETG Coated Overlay ( PETG Coatd Film) for PETG Card body production (Model: MCO-PETG) has such features as impact resistance, high temperature resistance, anti-static, abrasion, folding and high strength. It is widely used for the production of high-end credit cards, ID cards, special packaging and printing industry.

Parameters :

1). Size: in reel or in sheet as 210*297mm ( A4 ) , 310*480mm ( A3 ) or as per customer requirements

2). Normal thickness in mm: 0.04,0.05,0.06,0.08,0.10

3). Color : Transparent with one- side glue coating on surface.

4). Package method : in reel ,or 500 sheets per bag, 4 -8 bags per carton or customized, and the cartons are piled up and firmly fixed on solid plywood pallets

5). Storage condition : Sealed, moisture-proof, room temperature under 40℃ , Keep It horizontally, avoid heavy pressing and direct sunlight .

| Product name | Transparent PETG Coated Film For PETG Plastic Card Body Production |

| Color | Transparent or clear |

| Thickness Range | 0.04- 0.1 mm |

| Vicat softening point (B50) ℃ | 74±2 |

| Vicat softening point (A120) ℃ | 78±2 |

| Tear strength | >65 |

| Density | 1.20 ±0.05 g/cm³ |

| Heating shrinkage ratio 105 ℃/10min | ≥-8.0 % (longitudinal) &≥-4.0 %(transverse) |

| Surface Dyne (dynes/cm) | ≥38 |

| Glue coated | With one-side glue coating |

| Peel Strength (90°, | ≥6.0 N/cm |

| Aging time (65℃ temp./95% humidity ) | >200 hours |

| Suitable ink | offset and silk screen printing UV ink, Pigment and dye ink for inkjet printing as well as digital printing ink |

| Packing | PE Film inside + Carton box +Pallet |

| Advae | Excellent strength and abrasion resistance, high and low temperature resistance; suitable for card body performance and anti-counterfeiting technology requirements, such as id card, driving license, e-passport, etc |

Recommended Production Laminating parameters:

| Laminating parameters | Laminating Unit | Heat Laminating | Cool Laminating |

Temp | 110~130°C | ≤25°C | |

Time | 25min | 15 min | |

Pressure | ≥5Mpa | ≥5Mpa |

| 3. Application for High-adhesion PETG Coated Overlay or Film for PETG Plastic Card Body Production |

It is widely used in such cards as anti-fake IC cards, driving license card, transportation card and passport etc.

PETG material is quite different from PET and PC. PETG plate has outstanding toughness and high impact strength, its impact strength is 3-10 times more than ordinary plastic plate, and it has a wide processing range, high mechanical strength and excellent flexibility. Compared with PVC, it has high transparency, good luster and easy to print. At the same time, PETG has environmental protection advaes, and it can be recycled without polluting the environment. PETG sheet has low flammability, good fire resistance, no combustion support, low smoke emission, no harmful substances after combustion.![]()

1). Excellent strength and wear-resisting.

2). High temperature and low temperate resistance.

3). Perfect application for anti-fake IC cards, driving license card, transportation card and passport etc.

4). Environment-friendly material.

5). Longer service life.

| 4. Packaging for High-adhesion PETG Coated Overlay or Film for PETG Plastic Card Body Production |

In standard export carton and are packed on plywood pallet

![]()