0.12mm Customized Offset Printing Pvc Core Sheet With Ink Adhesion

Product Details:

| Place of Origin: | China |

| Brand Name: | MK |

| Model Number: | MOP-W |

Payment & Shipping Terms:

| Minimum Order Quantity: | 20000 sheets or 2 tons |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 100 or 200 sheets per PE bag, all the bags are firmly piled up and fixed on the solid plywood pallets |

| Delivery Time: | 10-15 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10-15 million square meters per month |

|

Detail Information |

|||

| Thickness Tolerance: | ±5% | Surface Tension Dyne/cm: | ≥35 |

|---|---|---|---|

| Vicat ℃: | 77±2 | Feature: | Excellent Ink Adhesion With Strong Peeling Strength After Lamination |

| Application: | Suitable For The Whole Series Of Offset Printer And Silk Screen Printer. | Supply Ability: | 500000 Sheet/Sheets Per Month |

| Highlight: | Ink Adhesion PVC Core Sheet,Offset Printing PVC Core Sheet,0.12mm PVC Core Sheet |

||

Product Description

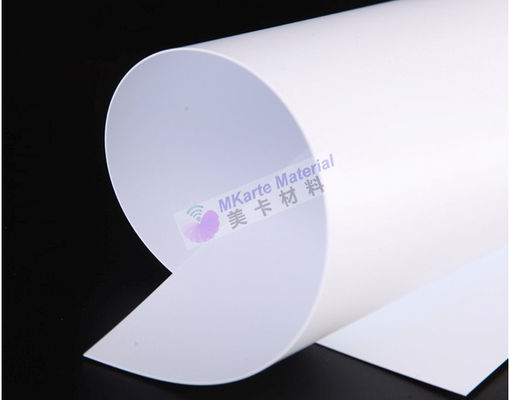

Customized Size White Offset Printing PVC Core Sheet With Excellent Ink Adhesion

1. Introduction of Customized Size White Offset Printing PVC Core Sheet With Excellent Ink Adhesion

This kind of ordinary PVC sheet can be used for laminating, non-laminating, printing, coating and

cutting, such as membership cards and calendars.

1. Thickness: 0.12-0.76mm

2. Color: Milk White (MOP-W-NF model)/Snow White (MOP-W-F model)

3. Suitable printer models: The whole series of offset printer and silk-screen printers

4. Package method: 100-200 sheets per PE bag, all the bags are firmly piled up and fixed on the solid plywood pallets.

5. Storage condition: Sealed, moisture-proof, room temperature under 40℃

| Item | Index | |

| Tensile strength | Longitudinal MPa | ≥45 |

| Transverse MPa | ≥40 | |

| Vicat ℃ | 77±2 | |

| Surface Tension dyne/cm | ≥35 | |

| Heat shrinkage rate% 140℃ 10min | Transverse ≤5 | |

| Longitudinal ≥-10 | ||

| Squareness mm | ±1 | |

| Thickness tolerance % | ±5 | |

| Roughness μm | Ra,μm | 0.7~1.4 |

| Rz,μm | 4~9 | |

![]()

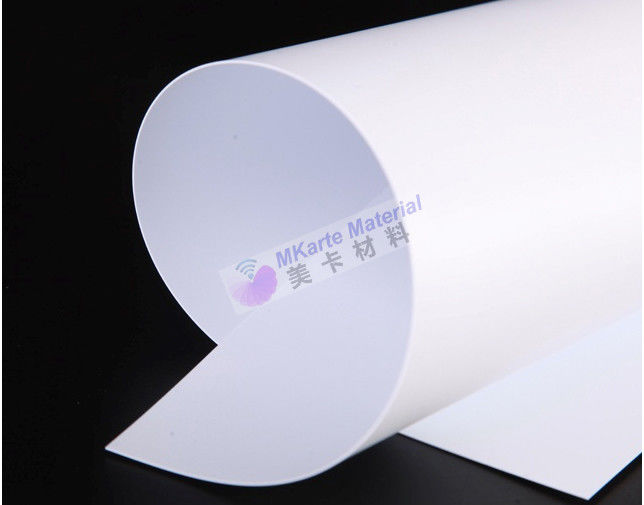

2.Technical Specification of Customized Size White Offset Printing PVC Core Sheet With Excellent Ink Adhesion

1). Low dust

2). Excellent stable quality

3). Exact sheet size cutting and thickness control

4). Low static easy for sheet feeding

5). Smooth roughness

6). Adjustable VICAT degree

7). Adjustable Opaque degree

8). Perfect packaging for transportation

9). Special formulation according to each client's requirement

10). Surface tension can over 40 Dyne

11). Less than15 days Short Lead Time

12). Best after sell service

| Size | in sheet A4,A3 or custom-made ( ( tolerance +/-0.5mm ) |

| Thickness | 0.12-0.76mm (tolerance +/-5%) |

| Color | Milk White (MOP-W-NF model)/Snow White (MOP-W-F model) |

| Coating description | digital ink coating on one side and lamination glue coating on another side. |

| Package method | 100-200 sheets per PE bag, all the bags are firmly piled up and fixed on the solid plywood pallets. |

| Storage condition | Sealed, moisture-proof, room temperature under 40℃ , Keep it horizontally, avoid heavy pressing and direct sunlight |

*Customized design is availalbe.

![]()

3.More Details of Customized Size White Offset Printing PVC Core Sheet With Excellent Ink Adhesion

It is mainly used for making credit card. Such material can achieve telegraphing (embossed), the material does not contain the substance for entering and modifying magnetic materials, capable of being labeled with magnetic stripe and encapsulated module, usually, it is matched with overlay film for use. PVC Bank Card Base is mainly used for bank, capable of making credit card, financial IC card.

![]()

Product Advae:

1. Smooth and Uniform Surface

It is waterproof and has very good smooth surface, and is non-deformable.

2. Reliable Electrical Insulation

It is widely used for different electrical equipment.

3. Excellent Chemical and Corrosion Resistance

It can withstand the erosion of a variety of chemicals.

4. Good Impact Resistance

It has good impact resistance, pressure-resisting and durability.

5. Easily Formed

It is easily formed due to good plasticity, which is suitable for die cutting, vacuum forming and folding.

6. Wide Usage

It can be laminated with uncoated overlay film after uv offset priting or screen printing.

![]()