Superior Aging Resistant PVC Card Material Strong Adhesion Overlay Film

Product Details:

| Place of Origin: | China |

| Brand Name: | MKarte |

| Model Number: | MCO-W |

Payment & Shipping Terms:

| Minimum Order Quantity: | 30000 sheets or 2 tons |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 50 or 100 or 200 sheets per bag, 10 bags per paper carton, and the cartons are piled up and firmly fixed on solid plywood pallets |

| Delivery Time: | 10-15 work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 3 million tons per month |

|

Detail Information |

|||

| Coating: | Coating On One Side,also We Have Uncoated Overlay | Size: | In Reel Or Sheet, A4, A3 Or As Per Customer Requirements |

|---|---|---|---|

| Normal Thickness: | 0.04,0.05,0.06,0.08,0.10mm | Thickness Tolerance: | ±10% |

| Suitable Ink: | Offset And Silk Screen Printing UV Ink, Pigment And Dye Ink For Inkjet Printing As Well As Digital Printing Ink | Roughness (μm): | Ra 0.5~1.8 |

| Highlight: | pvc id card material,plastic card material |

||

Product Description

Strong Adhesion PVC Overlay Film - PVC Card Material Suitable for Card Production

1. Strong Adhesion PVC Overlay Film - PVC Card Material - Introduciton

Brief Introduction:

Strong Adhesion PVC Overlay Film - PVC Card Material is suitable for laminating with conventional ink and UV ink. It could reach excellent peel strength as using Water Based Laminating Varnish . It provides superior aging resistance performance to other similar products, no color change and deformation after lamination. Laserable Coated Overlay is also offered.

![]()

Strong Adhesion PVC Overlay Film - PVC Card MaterialMCO-W model is suitable for laminating with most PVC sheets printed by various printers. It features high adhesion, no color change and deformation.

It is applicable to almost all sheets printed by various ink. It features excellent peeling strength and long aging time.

Technical Parameters:

| Item | Parameters | |

| Vicat (℃) | 72±2 ℃ | |

| Shrinkage (%) | ≤10% | |

| Tensile Strength (MPa) | MD | ≥40 |

| TD | ≥35 | |

| Roughness (μm) | Ra | 0.5~1.8 |

| Rz | 3~9 | |

| Thickness (mm) | 0.04~0.1 |

|

2. Strong Adhesion PVC Overlay Film - PVC Card Material - Parameters

Technical Parameters:

| Item | Parameters |

| Vicat softening point | 72±2 ℃ |

| Heating Shrinkage ratio | ≤10 % |

| Tensile Strength | ≥40 MPa |

| Normal thickness in mm | 0.04,0.05,0.06,0.08,0.10 |

| Peel Strength (90°, 300mm/min) | ≥6.0 N/cm |

| Aging time (65℃ temp./95% humidity ) | >200 hours |

| Suitable ink | offset and silk screen printing UV ink, Pigment and dye ink for inkjet printing as well as digital printing ink |

Parameters:

1). Size: in reel or sheet, A4, A3 or as per customer requirements

2). Normal thickness: 0.04,0.05,0.06,0.08,0.10mm

3). Color: transparent with one-side glue coating.

4). Package method: by reel or 500 sheets per bag/4-8 bags per paper carton, or as per customer requirements. All the cartons are firmly piled up and fixed on the solid plywood pallet.

5). Storage condition: Sealed, moisture-proof, room temperature under 40℃, Keep it horizontally, avoid heavy pressing and direct sunlight.

3. Strong Adhesion PVC Overlay Film - PVC Card Material - Application

![]()

Characteristics:

● Suitable for conventional ink and UV ink, excellent peel strength even with pearl ,gold ,silver and dark color inks.

● Keep the fluorescent anti-forgery mark clearly.

● Non-Sticky and easy for magnetic stripe tape-laying.

● Abrasion resistant , prolong the life of cards.

● Environment friendly, no solvent or gas discharged.

◆Product Category and Laminating Condition:

| Product Category | MCO-W | ||||||

| Application | ID Card,Social Security Card,Bank Card,etc | Bank Card,Shopping Card,etc | Membership Card,Commercial Card,etc | ||||

| Suggested Laminating Condition | Laminating Unit | Heat Laminating | Cool Laminating | Heat Laminating | Cool Laminating | Heat Laminating | Cool Laminating |

| Temp | 130~150℃ | ≤25℃ | 130~150℃ | ≤25℃ | 135~155℃ | ≤25℃ | |

| Time | 25min | 15 min | 25min | 15 min | 25min | 15 min | |

| Pressure | ≥5MPa | ≥5MPa | ≥5MPa | ≥5MPa | ≥5MPa | ≥5MPa | |

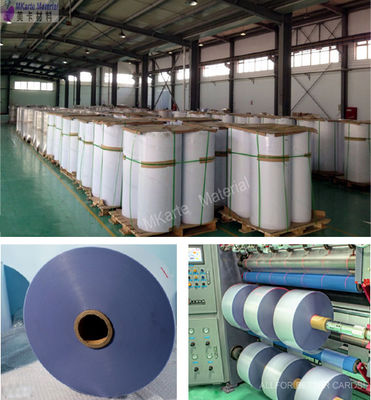

4. Strong Adhesion PVC Overlay Film - PVC Card Material - Packing

| Product Test Report | ||||||

| Product Name:Normal PVC coated overlay | ||||||

| SN | Inspected items | Unit | Inspection standard | Test result | ||

| 1 | Fabric width | mm | ±1 | OK | ||

| 2 | Length | mm | ±1 | OK | ||

| 3 | Width | mm | ±1 | OK | ||

| 4 | Thickness | mm | ±10% | OK | ||

| 5 | Squareness | mm | ≤1 | 0.3 | ||

| 6 | Density | g/cm3 | 1.25±0.05 | 1.26 | ||

| 7 | Pulling Strength | MD | MPa | ≥40 | 42 | |

| CD | ≥35 | 40 | ||||

| 8 | Heating Shrinkage rate |

MD | % | ≤+30 | 26 | |

| CD | ≥-45 | -42 | ||||

| 9 | Vicat softening point | ℃ | 76±4 | 75.8 | ||

| 10 | peeling strength | N | ≥3.5 | 4.9 | ||

| 11 | Surface quality | The surface is flat without wrinkles, holes or glue drops, and the color is correct. | ||||

Packing:

Outside:Carton Inside:PE bag

Storage:

Keep package sealed and moisture-proof , room temperature under 40℃.

Stacking height should not exceed one meter.

Keep horizontally, avoid oppress heavily and direct sun light.

Shelf life: Two years.

![]()