80 N/Mm 3mm Woolen Felt Cushion Laminated Pad For Credit Card

Product Details:

| Place of Origin: | China |

| Brand Name: | MK |

| Model Number: | MRP-2 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100 pcs |

|---|---|

| Price: | USD 5 -30 per sheet |

| Packaging Details: | packed with PE bags and paper carton |

| Delivery Time: | 5-15 working days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram, D/A, |

| Supply Ability: | 8 thousand pieces per month |

|

Detail Information |

|||

| Surface Material: | Heat Resistant Wool | Size: | A4, A3 Or Customized |

|---|---|---|---|

| Thickness: | 3mm | Heatproof Performance: | 200℃ |

| Tensile Strength: | 80 N/mm | Hardness SHORE A: | 55±5 |

| Color: | White | Core Material: | Silica Gel |

| Highlight: | 3mm Cushion Laminated Pad,80 N/mm Woolen Felt Cushion Pad,Credit Card 3mm Laminated Pad |

||

Product Description

Woolen Felt Cushion laminated Pad, Press Pad used as PVC Card Material in Lamination

(also named: felt cushion pad, lamination pad, rubber pad, card laminator cushion pad, silicon rubber pad, plastic card lamination pad, card production material)

1. Woolen Felt Cushion laminated Pad, Press Pad used as PVC Card Material in lamination- Introduction

Woolen Felt Cushion laminated Pad MRP-2 is designed for the lamination process for various plastic cards including bank card, credit card, and royalty card. It works with lamination steel plate in the plastic card lamination process.

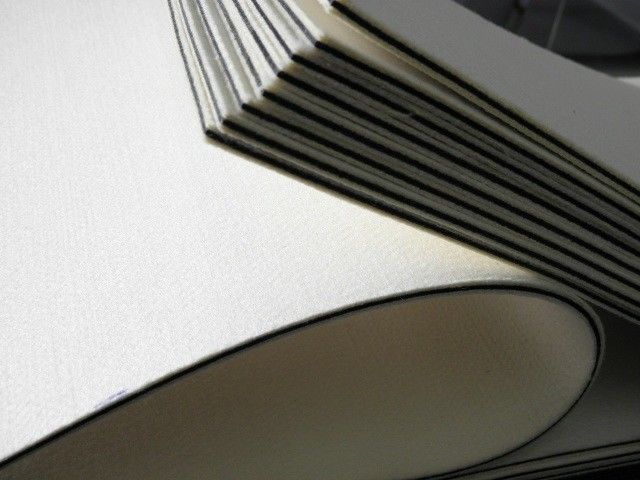

The structure of white silicon cushion pads is Woolen felt layer on the surface layer with black rubber in the middle .

Our lamination Cushion was be made by silica gel and heat resistant wool, it can be widely use for cards laminator. it can avoid scratch, bubble, fish eye, water spots during lamination process to improve your yield rate.

![]()

2. Woolen Felt Cushion laminated Pad, Press Pad used as PVC Card Material in lamination- Features

Key Features:

1). It is heatproof with great durability, which can well meet the technological requirements in plastic card lamination.

2). It can transfer heat quickly and evenly, which can improve production efficiency and energy conservation.

3). It has good performance of high temperature resistance and excellent elastic resilience.

4). It has good cushioning performance to avoid the damage and scratching resulting from direct contacting between laminator template and lamination steel plates, which can extend the service life of both lamination steel plates and templat

![]()

| Function | Used for plastic card laminator, working with lamination steel plates |

| Service life | one year |

| Material | Woolen felt layer on the surface layer with black rubber in the middle |

Technical Parameters:

| Heatproof performance | 200℃ |

| Tensile strength | 80 N/mm |

| Adhesion | 80 N/mm |

| Hardness SHORE A | 55±5 |

| Thickness | 3mm |

| Length and width | A4, A3 or custom-made size (size tolerance: ±1mm) |

3. Woolen Felt Cushion laminated Pad, Press Pad used as PVC Card Material in lamination- Application

The pad is also known as felt cushion pad, lamination pad, rubber pad, card laminator cushion pad, silicon rubber pad, plastic card lamination pad or card production material.

| Production Name | Cushion for lamination | |

| Factory Ref. No. | MRP-1 | MRP-2 |

| Surface Material | Silica gel with embossing | Heat resistant wool |

| Core Material | Fiberglass | Silica gel |

| Hardness | 55 ± 5(Shore A) | 50 ± 5(Shore A) |

| Tensile strength | 80 (N/mm) | 60 (N/mm) |

| Adhesion | 4.5 (N/mm) | 4.5 (N/mm) |

| Heat-resistant | 200 °C | 200°C |

| Color | White | White |

| Sheet Size | customer size*3MM |

customer size*3MM |

4. Woolen Felt Cushion laminated Pad, Press Pad used as PVC Card Material in lamination- Packing

Laminating pads are suitable for manufacturing kinds of ISO baning cards, cards and smart cards.Raw materials are all for anti-high temperature and anti-high pressure. Meeting the requirements of laminating process, as the professional card consumables, they have been widely using for improving the production efficiency and saving energy because of the feature of thermal conductive fast and uniform. Have excellent bibulous performance, can effectively eliminate the risks of bubbles and watermarks on card surface, greatly improved the qualification rate of products, and with good cushioning properties, they can avoid the scratches linked to the hard touching between the heating plate and the trays, benefited to the long using life of above both.

![]()